How a Common Material Is Quietly Changing Construction in India

In 2015, devastating floods brought large parts of Tamil Nadu, India to a standstill. More than 470 lives were lost, over 4 million people were affected and a local economy shaken by the scale of destruction. For many, the floods were seen as a natural disaster. But for those who understood the deeper causes, the damage pointed to a man-made problem: decades of uncontrolled river sand extraction.

A Fragile System

For years, construction across India had relied heavily on river sand. Extracted from riverbeds, it had long been considered the standard for concrete work, preferred simply because it had always been used. But growing demand led to overextraction. Across Tamil Nadu, riverbeds were stripped of sand faster than it could be regenerated. In rivers like the Thamirabarani and Palar, the beds deepened by up to 15 meters in just two decades. The consequences became visible not only in degraded ecosystems but in infrastructure and communities. When sand is removed, riverbanks lose stability, water tables drop and rivers lose their ability to manage heavy rainfall.

These effects became undeniable during the 2015 floods. As the rains fell, swollen rivers surged through weakened channels. Drainage systems failed and urban centers flooded rapidly. The environmental consequences of sand extraction had long been known to scientists and regulators, but in this instance, the impact was sudden and tragic.

In the years following the floods, authorities began to more aggressively restrict river sand extraction. The intention was clear: protect what remains of the rivers and communities from flooding. But this necessary regulation brought new challenges. River sand became expensive, scarce and often difficult to obtain legally. For the construction industry, especially small-scale builders and individual homeowners, the cost of sand was no longer manageable. Alternatives were needed.

An Alternative With Promise

Among these alternatives was manufactured sand, or M-sand, a material produced by crushing hard stones into fine aggregates that mimic the properties of river sand. Technically sound and environmentally sustainable, M-sand emerged as a promising option. But adoption was far from immediate. People believed river sand was better simply because it had always been used. Even when M-sand was proven to be stronger and more consistent, many builders were hesitant to make the switch. It was a matter of perception, not performance.

Aruna Blue Metals had been one of the few companies promoting M-sand as a viable alternative for years, but progress was slow. While large developers with engineering teams could analyze and verify the quality of M-sand, the majority of the housing sector in India consists of individual home builders and small contractors, many of whom rely on word of mouth, tradition and personal experience to make their decisions.

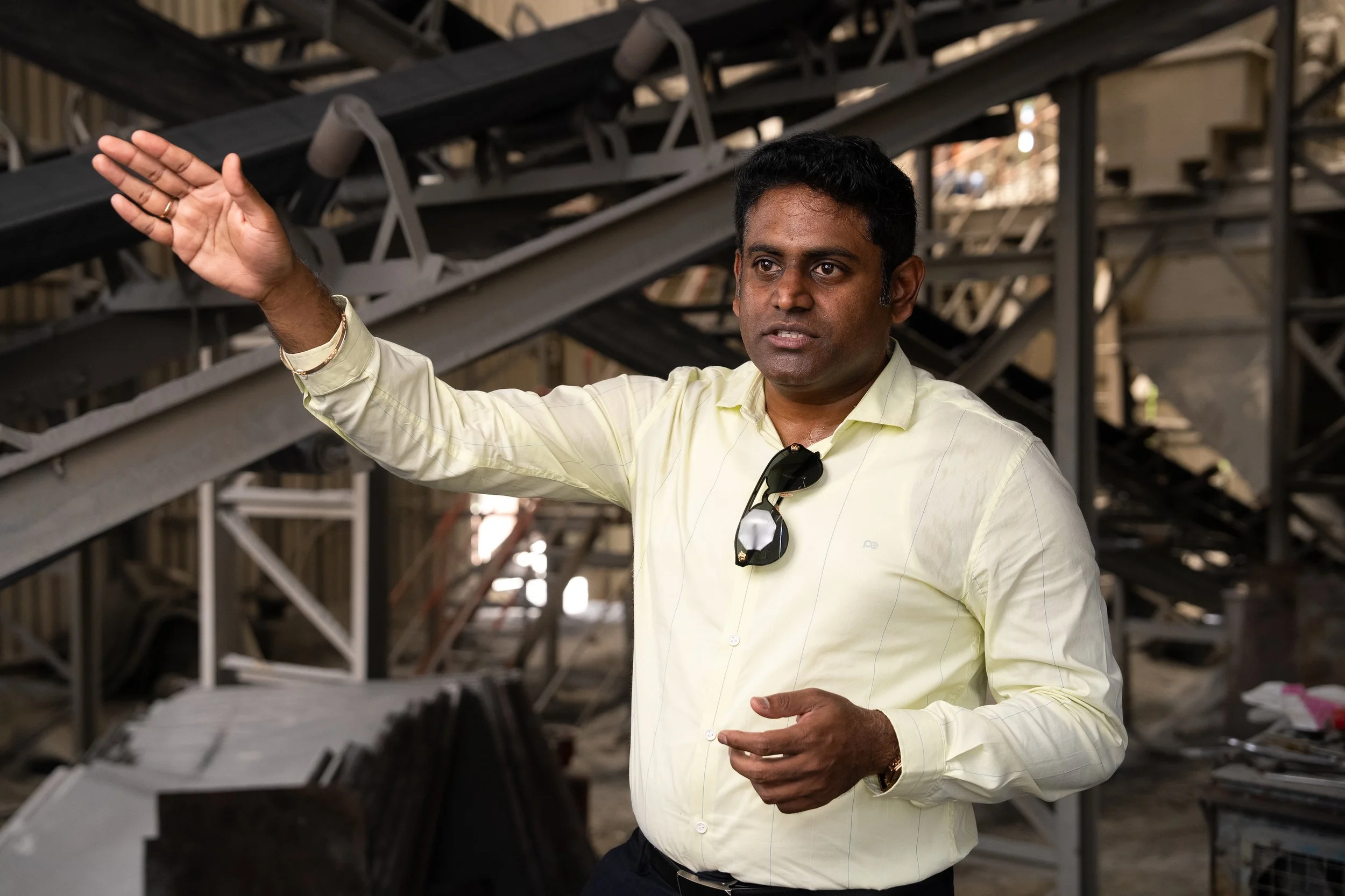

“We saw the crisis coming. We knew India needed a sustainable, high-quality sand alternative, but breaking into the market, and mainly direct customers, wasn’t easy,” says Senthil Kumar, CEO of the company. Changing the materials people use to build their homes requires more than just data, it requires trust. His company found early success selling M-sand to developers building apartment complexes and commercial structures. Yet to create broader impact, they needed to reach the everyday builder: families building a single home, masons overseeing local projects and hardware retailers supplying small batches.

Turning a Material Into a Movement

This is where the Terwilliger Center for Innovation in Shelter (TCIS) stepped in. Recognizing the potential of M-sand, not only as a building material but as a tool for systemic change, TCIS began working with Aruna Blue Metals to expand its reach and impact. One of the first priorities was education. TCIS helped Aruna organize training sessions, product demonstrations and hands-on workshops targeting the people who influence building decisions on the ground: masons, contractors, site engineers and even homeowners themselves. These sessions explained how M-sand is produced, how it performs compared to river sand and why switching makes sense both financially and environmentally.

Yet another obstacle soon became apparent. Even as confidence in M-sand grew, access remained a challenge. Smaller buyers often struggled to find reliable suppliers nearby, especially in semi-urban and rural areas. Aruna’s existing supply model, built for bulk orders, was not equipped to serve this growing base of small-scale users. With TCIS’s support, Aruna revised their logistics model. New distribution hubs were established closer to local markets, transport costs were reduced and partnerships with regional retailers were formed. The supply chain became leaner and more responsive, making it possible for M-sand to reach areas that had previously depended entirely on river sand.

The results were significant. “With TCIS’s support, our M-sand sales grew by 25% in just a few months,” Senthil shares. “More importantly, we saw a complete shift in who we were selling to.” Prior to 2019, 80% of Aruna’s business came from developers and large contractors. Today, that figure is reversed, with 80% of sales to individuals, families and small-scale builders.

Getting M-Sand Into the Right Hands

Standing on a quiet jobsite outside the city, masons like Mr. Chinnaiyan are a testament to this shift. He supervises a small team laying bricks for a new home. Over the course of his two-decade career, he has been involved in the construction of more than 300 houses. Once a brick-carrying helper, he is now a supervisor, trusted by dozens of families to build their homes.

His company, Aishwarya Constructions, named after his daughter, uses M-sand almost exclusively. “At first, we were unsure,” Mr. Chinnaiyan admits. “But after seeing how consistent it is, and how easy it is to work with, we made the switch. It’s not just better—it’s smarter.” For Mr. Chinnaiyan and his team, the benefits are clear. M-sand is easier to procure, more affordable and doesn’t vary in quality from one batch to the next. For the homeowners he works with, the cost savings can be significant. And for the environment, the change is meaningful. “People don’t realize,” Senthil says, “that every truckload of sand taken from a river is making the next flood more likely. When we switch to M-sand, we’re not just saving money, we’re protecting lives.”

The broader impact is systemic. As the construction industry begins to embrace sustainable materials, the market shifts. Ecosystems recover. Rivers can begin to heal. And families, often those building their very first home, can do so affordably, without compromising the future. Thanks to the partnership between TCIS and companies like Aruna Blue Metals, materials like M-sand are no longer the exception, they’re becoming the norm. And in the hands of masons like Mr. Chinnaiyan, they’re shaping stronger homes, and a more resilient India.

About the Partnership

The Hilti Foundation supports Habitat for Humanity’s Terwilliger Center for Innovation in Shelter (TCIS) to bring affordable, sustainable housing solutions to low-income families. Together, they work to develop and introduce practical, market-based products that can improve living conditions for underserved communities. Focusing on three pilot regions—Peru, India, and the Philippines—the initiative aims to prove that these solutions can succeed in real-world conditions. In India, next to M-sand, the partnership is making strong progress, helping families access roof cooling coatings that reduce indoor temperatures and improve comfort in hot climates.